Stonewood Homes

ViAGO Client. TOC3 practitioner: Andrew Kay (Project Manager) & Andrew Cranwell. Credit to Phil Spitalney TOC Contractor.

Product: Custom Built Homes

Issues

- Long lead time to build homes

- Unhappy customers

- Unhappy sub contractors

- High Stress levels

- Poor profitability

Action taken, changes made

- On-site consulting project: Critical Chain Project Management

- Installed Critical Chain based scheduling and Pipeline Management

- Supervisors and Subcontractors trained to follow the new system

|

Measure |

Before |

3 months after CC project installed |

Improvement |

|

Lead Time to build standard 3 Br modern home |

110 – 120 days Industry standard |

73 Days consistent plus or minus 5 days |

30% - 35% lead time reduced |

|

Cash Flow |

Not bad, sometimes going to 30-60 days. |

Great |

Suppliers/contractors paid on time, and before time if they are in a tight spot. |

|

Progress Payments |

Unreliable |

Reliable on time |

More projects hitting payment stages more regularly = predictable cash flow |

|

Profitability |

Struggling to break even |

Tangible difference. |

As a volume business the ability to produce more = Better returns. |

|

Customer Satisfaction |

Lots of complaints |

Lots of praise |

One home on the market 2 weeks early (63 day build). |

|

Contractor Satisfaction |

Lots of complaints |

Lots of praise for everyone |

New levels of trust and payments on time |

|

Stress levels |

High – many sleepless nights |

Much lower, ability to switch off and leave it to others. |

Taken holidays for first time in years |

New Zealand Press:

Tauranga Gets Gold!

“Stonewood Homes, Matamata New Zealand enjoyed phenomenal success with two gold medals in the House of the Year Awards 2008. They won the prestigious Category Winner and Gold Medal for their entry in the Homes $350,000 to $450,000 category.

“Some of the standout results (they are all standout, these are the real biggies) …

- I can sleep at night with the knowledge that the projects are where they should be and there is a workable plan for the completion of the home.

- Clients have a completion date that is real.

- I have been away on holiday twice since the implementation of our project board, this has been without the need to take a phone for fear of the need for my direction. More importantly upon my return everything is still in order.

- We have clients that are in their completed homes that consider us their friends after the process of building their home. They tell us their personal news and take delight in us sharing parts of our lives with them. This is a real breakthrough.”

Kevin Norris, Owner Stonewood Homes, Matamata, New Zealand

The following client has achieved substantial results with TOC after Lean and some Six Sigma practices where already embedded in the organisation. So if you have already implemented Lean or Six Sigma here is proof that you can leverage your system even further. This client operates an 11 hectare plant with more than 580 employees

ELECTROLUX Case study

From Imminent Closure to the Star Jewel in the Crown

Refrigeration Plant, Orange NSW, Australia

Jason Furness, General Manager, Electrolux, 2009 Product: Domestic Refrigerators and Freezers

Main Issues

- Unable to give the market what it wants when it wants it

- Too much cash tied up in the system

Solution – On site TOC Implementation program

- Installed “Make to Availability” Production Scheduling and Replenishment Solution

- Installed Critical Chain Project Management in Engineering for Product Cost Reduction, Facilities Management and New Product Development

- Implemented Throughput Accounting and new Measurements

- Series of TOC Education Workshops and the Management Skills Program

- Installed DBR Production Scheduling and Buffer Management

|

Main Plant |

Before |

After 12 months |

Percentage Change or Comment |

|

Finished Goods Inventory |

40 days stock Aug 07 |

12 days stock Jun 09. Replenishing daily to meet daily market demand |

48% reduction in FG inventory |

|

Back Orders |

Average 20 Days |

Average 2 – 4 days |

>50% improvement to customer service |

|

Production Flexibility |

Make to 3 month forecast |

Make to actual sales 2 days turnaround. Highly flexible. |

Increased production by 30% - 35% |

|

Cost Reduction |

Budgeted $2.5m in direct materials |

Achieved $4.1m |

Achieved additional $1.6m in savings |

|

Chest Freezers |

Before |

After 3 weeks |

|

|

Output |

Between 140 – 170 Units/day - majority small capacity units |

Between 220 – 250 Units /day Better mix with larger capacity units + higher margin |

Greater than 30% increase in capacity |

|

Profitability |

Poor |

Dramatic improvement |

Profitability increased >50% |

Other Results

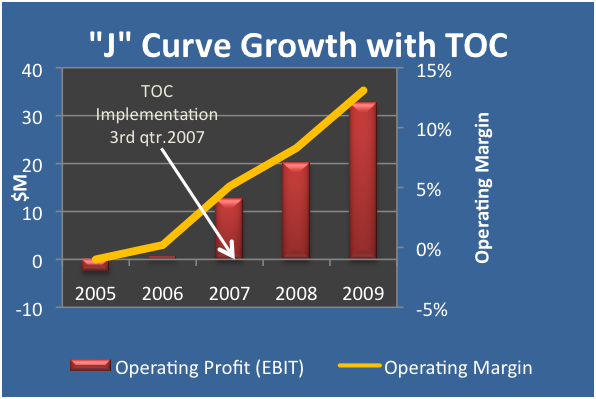

- Operating margin increased from 5.1% to 13.1%,

- Profit increased by $19.88m,

- Volume went up by 6.5%, with no capital investment in capacity.

- 50% increase in exports 2008 with zero investment and $AU 1.00 at $US 92 cents

- Won back $14m in sales for Sep 09

- Brought production for a product back into Australia from low cost country

- Generated $3m in cash from a $30k investment

- All new model projects on time, on budget and on quality (30% less time required than previously)

- Quality continues to improve with 85% new SKU’s, Exported product to China, Bank of hardy perennial problems being resolved very quickly using TOC thinking tools, Stable workforce and increasing in number as the company grows, Skills now inbound, General Manager gets a lot of thinking time to work on the business.

“TOC is the best method for building common understanding and agreement that I have seen in over 2 decades in industry that has taken me around the world” Jason Furness, GM, Electrolux Refrigeration

Profitability

- Profits increased by $19.2m 2009 up by 59% during the worst economic conditions since the Great Depression

- Margins increased from 5% in 2007 to 13.5% in 2009 (during a global recession)

Cash

- Additional $20m released into the system by reducing inventory

50% increase in exports 2008

- Zero investment?AUD at 92c USD

Won back $14m in sales for Sept 09 qtr

- yielding $3m extra in cash?for a $30,000 investment

All new model projects delivered on time

- On budget, On quality

Finished Good Inventory Reduction

- From 40 days cover in Aug 07 to 12 days cover June 09Cost Reduction Projects

- Direct material cost reduction saving $2.5m more than budget Expecting $4.1m by end of year 2009

Production Plant Flexibility

- From building to a 3 month forecast in 2007 to responding to customer orders in 3 days.

Quality

- Warranty call rate down by 50% to 4.75% on 2 years ago. The lowest it has ever been. Electrolux are setting records in this area?and continues to improve with new SKU's on 85% rating (first trial builds)

- Hardy perennial problems being solved systematically

People

- Workforce is stable (and happy by and large)

- Increasing because we need more people?Skills are now transferred into the company ?People are approaching the company to work here. 18 months prior we struggeld to attract people.

Electrolux in the community

- Regarded very highly within the region as an employer of choice (see local press feature article)?2007 receiving poor media reports, 2009 Electrolux success being publicised in the region through local media.

General Manager

- Gets a lot of think time.

video

Exepron

NEWS

In a nutshell

Login Form

TOCICO

Certified Practitioners

The Goal, By Eli Goldratt, Anniversary 3rd Edition in stock $45.00 plus postage. Immediate delivery anywhere in Australia

TOC Expert (Day)

Just like Jonah in "The Goal" have a leading TOC Expert (Jonah) visit your site for one day.