Theory of Constraints is not a secret but it might well as be.

Theory of Constraints is not a secret but it might well as be.

To achieve rapid, significant and lasting business improvement demands a profound change in thinking. Thinking has to shift from local efficiency to system effectivess. They are not the same. The prevalent belief is that if we maximise efficiency everywhere then the whole system will perform better.

Since the mid 1980’s many hundred's of businesses around the world including some in Australia and New Zealand through a change in thinking have been achieving rapid and sustainable growth even during difficult economic times. Whilst many organisations are still struggling with the effects of the recent Global Financial Crisis the large majority of these “other” companies are flourishing!

The reason they are flourishing is because they have implemented the Theory of Constraints (TOC). TOC was introduced to the world in 1984 by Dr Eliyahu Goldratt through his best selling business novel “The Goal”. An independent research study1 of TOC implementations in 78 organisations found consistently remarkable results achieved in very short time frames:

- Lead Times reduced 69%

- Cycle Time reduced 66%

- Due Date Performance improved 60%

- Inventory Levels reduced 50%

- Revenue/Throughput increased 68%

Source: 1The World of the Theory of Constraints, Vicky Mabin and Steven Balderstone, St. Lucie Press, 1999.

Theory of Constraints and the Scientific Systems Approach

The Theory of Constraints is a broad philosophy and body of knowledge developed by Dr Eliyahu M. Goldratt based in the application of systems thinking and scientific principles mainly to human systems and specifically to organisations.

Systems thinking allow us to look at the entire organisation holistically. Using cause and effect logic we can quickly find the few real causes that prevent the business achieving its goals. This is a major breakthrough for achieving rapid and sustainable business improvement in complex environments.

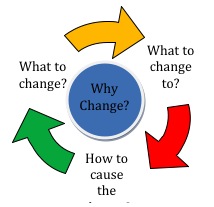

TOC is applied logically and systematically to answer 3 essential questions intrinsic to any process of continuous improvement:

- What to change (and why)

- What to change to

- How to cause the change

TOC postulates that the goal of business is to make more money now and in the future. This can be achieved by:

- Increasing Throughput

- Reducing Inventory

- Reducing Operating Expenses

To achieve the goal TOC provides 5 Focusing Steps for continuous improvement that must be followed in sequence:

- IDENTIFY the system(s) constraint

- Decide how to EXPLOIT the system(s) constraint’

- SUBORDINATE everything else to the above decision

- ELEVATE the system(s) constraint

- If in the previous step the constraint has been broken, go back to step

These Five Focusing Steps are the key to unlocking the systems hidden potential and the foundation for ongoing continuous improvement.

The Theory of Constraints consists of the TOC Thinking Processes (Jonah) and proven logistical solutions (or applications) to specific subject areas:

- Operations and Scheduling (Drum Buffer Rope, Simplified DBR)

- Critical Chain Project Management (CCPM)

- Distribution and Supply Chain Management (Replenishment)

- Finance and Measurement (Throughput Accounting)

- Marketing (Mafia Offer)

- Sales

- People Management

- Strategy and Tactics

- Thinking Processes (TOC/TP)

The components of TOC are ever evolving and have extended into several new and important areas including health and education.

Your system is only as strong as its weakest link What TOC suggests is get the most out of your current system before spending any more money.

What TOC suggests is get the most out of your current system before spending any more money.

To get the most out of any system we must know where to focus our improvement efforts. When we find the part that most limits our ability to achieve the goal of the system we are then compelled to find ways to leverage that part to maximise the throughput for the entire system.

In short find the weakest link and learn how to get the most out of it. It is the weakest link that determines the throughput for the entire system. It is the system’s constraint.

The constraint is the point of focus for all improvement effort. Why?

It determines the rate of money flowing through the system.

Stop the constraint and money flow stops, end of story!

This is very good news.

If we agree that business can be viewed as a system designed to make money now and into the future, then by using only existing resources we can dramatically improve performance.

The Theory of Constraints tools and methods enable us to rapidly identify the constraint(s) and implement solutions that focus the entire organization to maximize the throughput of the constraint(s) resolving problems that previously seemed impossibly complex and unsolvable.

![iStock_000007305840Small[1]](/images/stories/graphics/iStock_000007305840Small[1].jpg) The Theory of Constraints is about focus and leverage.

The Theory of Constraints is about focus and leverage.

Focus on and leverage the “weakest link”. When we do this it is almost impossible not to achieve rapid and massive step change improvement in the performance of the system as a whole. Focusing on anything else is just a waste of time, energy and money. Most other improvement methodologies ignore this fact.

Applying the TOC solutions quickly and powerfully leverages improvement throughout the entire system. This means that results are orders of magnitude greater than the effort applied. By doing so the business can rapidly achieve higher levels of Profitability, Cash flow and Returns on Investment.

What’s more life improves just about for everyone. When a system works for you we tend to be happier. When it doesn't work for you we tend to be a lot less happy. TOC helps transform chaotic systems into calm, predictable, reliable, smooth flow systems. A nice thing to have.

At this point you might be asking the following questions!

- Where are we currently focusing our improvement efforts - on the causes or the symptoms?

- Do we know where our weakest link is?

- Are we getting the most “bang” for our buck?

- How much waste are we generating by not focusing on the weakest link?

As unbelievable as it sounds applying TOC to your business generates significant measureable results immediately (in a matter of days or weeks). Independent studies have shown that the scale of financial and operational performance improvement in this time frame outperforms every other improvement methodology by a minimum 4:1.

The next stepWe would be more than delighted to discuss how these principles of TOC work to generate these kinds of results and you can consider the possibilities for yourself, your business and your people. That is what we are here for. It does not cost anything to ask. And it can be just the right thing. You choose when the time is right to act.

Contact us now to discuss how we can help you transform your business and maximise profits