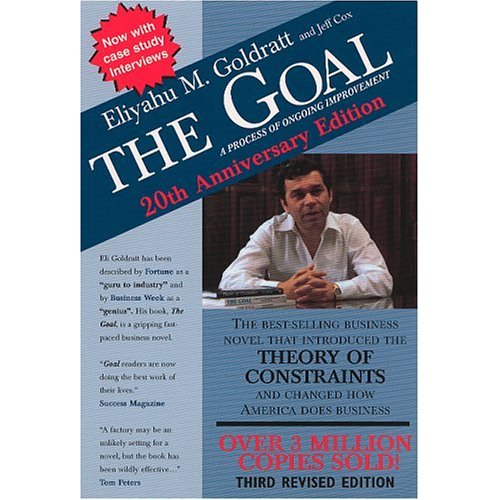

The Goal – A Process of Ongoing Improvement

By Dr. Eli Goldratt

A new hero is winning the hearts and minds of American Managers. The hero’s name is Alex Rogo, and thousands of executives know of his struggle as plant manager to save the UniCo factory in the town of Bearington from being shut down.

Rogo’s fans can recount how the division manager, Bill Peach, drove up in his crimson Mercedes with the Number One license plate and gave Rogo an ultimatum: “Al, this is it: You’ve got three months to turn this plant around.”

They can tell you how marketing executive Johnny Jones, who sits behind a glass-and-chrome table and wears Gucci loafers and silk socks, leaned on Rogo to process the orders of his top customers first. They know about Hilton Smyth, the self-promoter whose temporary elevation over Rogo made it seem for a moment that all was lost.

Most of all, they can tell you about Jonah, the imperious physicist who helped Rogo discover and pursue the proper goal, which is making money, not saving it. Armed with new understanding, Rogo and his comrades circumvented the baleful scrutiny of financial officer Ethan Frost and his obsolete cost-accounting practices and executed a stunning turnaround. Rogo ultimately realised that the principles he had learned apply to more than just manufacturing. They are in fact the basis of a philosophy of ongoing improvement whereby change becomes the norm rather than the exception, and short-term gains are merely positive reinforcement to keep going and reap long-term benefits.

Alex Rogo is a fictional character from a most unusual book, The Goal that has sold over 2,000,000 copies world-wide. Many companies tell of dramatic results after key people have read and implemented its ideas. A year after executives at Modine Manufacturing Co. read the book, they reported that work-in-process inventory had fallen by 70 percent. Their average manufacturing lead-time – from raw material to shipment – dropped from 12.7 days to 3 days. Absenteeism plummeted by more than 20 percent.

Many readers say they read the 274-page book in one or two sittings, unable to put it down. “I felt I was the main character and the situations were ours,” wrote one vice president of manufacturing. The enthusiasm of some readers seems to know no bounds. One called it “the single most important literary work concerning business that has or may ever come along.” Yet even management professors wrote excited letters, and some planned to use it in their courses. Kodak and General Electric managers were among those ordering copies for key personnel, and some orders were in the hundreds.

With the help of the diagrams woven into the story-line, readers can understand the scientific reason all systems tend to fall further and further behind schedule: Slowness accumulates in a system, and there are ceilings on how much catching up can be done. The Goal demonstrates that there are two types of resources in an organisation, bottlenecks and non-bottlenecks, and that this fact has “vast implications.” Bottlenecks, importantly, are not good or bad, but simply resources, human or mechanical, whose capacity is less than or equal to the demand placed on them. The challenge is to identify and use bottlenecks to control the flow of product through the plant and into the market. A crucial principle: An hour lost at a bottleneck is an hour lost for the entire system; an hour saved at a non-bottleneck is a mirage.

The principal author of The Goal is Eliyahu M. Goldratt, an Israeli physicist and management consultant. Goldratt says Alex Rogo illustrates that what executives need most “is not brainpower, but the courage not to run away from the problems.”

One of the people who has read and praised The Goal was the grand old man of manufacturing, Dr. W. Edwards Deming.